One of the primary reasons for Boeing’s growth over the last year has been due to a renewed focused on innovation throughout their supply chain.

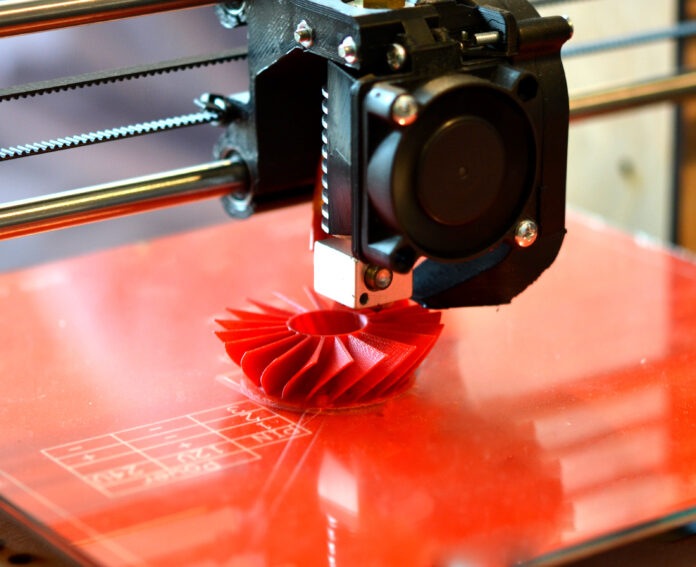

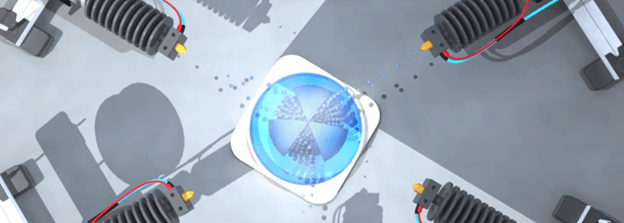

Boeing has already started to incorporate patent pending new 3D printing technology with a patent filed in July 2014 recently awarded in February 2016. This new technology is capable of printing objects while an object is simultaneously levitating. Why does this matter? This innovation removes the need for a platform in the fabrication process of aircraft parts. Any part can now be fabricated removing previous limitations on features. Today, Boeing is manufacturing 3D complex parts with virtually no setup cost.

The benefits of print “in air” are substantial. Magnetic fields levitate a base call a “nugget,” and this unique process doesn’t require the part to be built layer by layer from the bottom-up. This patent technology can print in any direction, allow for the range of complex parts modern aircraft require.

What’s the impact on the supply chain?

- Supporting materials do not wear

- Near real-time setup for a new fabrication process (all software based)

- Multi-dimensional printing accelerated by removing the need to print bottom-up, layer by layer.

Source: https://3dprintingindustry.com (Image)

Reference

Koslow, T. (2016). 3D Printing of Levitating Objects Patented by Boeing – 3D Printing Industry. Retrieved September 24, 2016, from https://3dprintingindustry.com/news/boeings-patents-new-technology-that-3d-prints-levitating-objects-67269/